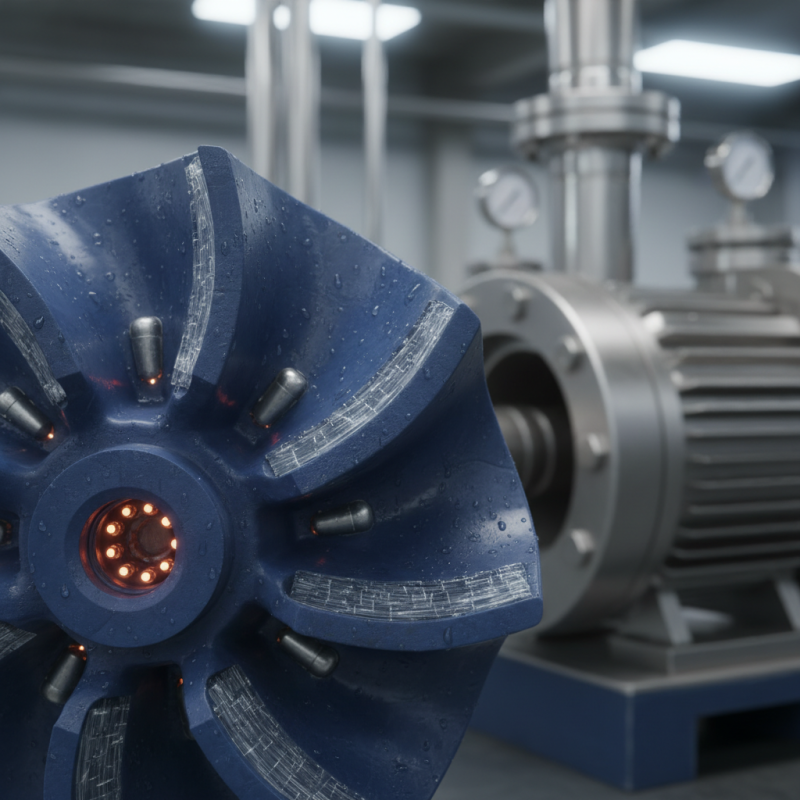

The demand for efficient and durable pumping solutions has led to significant advancements in design and materials. Rubber Pump Impeller technology has emerged as a crucial aspect in optimizing performance across various industries. According to a recent industry report, the global rubber pump impeller market is projected to grow by 8% annually, highlighting its increasing adoption in sectors such as agriculture, construction, and chemical processing.

Rubber Pump Impellers offer distinctive features, including exceptional resistance to wear and tear. This ability prolongs their lifespan compared to metal alternatives. Additionally, their flexibility enables better handling of abrasive and thick liquids. However, challenges remain, such as the need for better temperature resilience. Companies must consider these factors when selecting materials.

As industries evolve, understanding the future of Rubber Pump Impeller designs is essential. Innovations are needed to enhance performance and address current limitations. Analyzing feedback from users can provide insights into areas for improvement. Emphasizing durability while optimizing functionality will shape the direction of this market.

When considering the key features of 2026 top rubber pump impellers, flexibility is paramount. A rubber impeller can easily adapt to varying fluid types. This adaptability makes them suitable for diverse applications, from wastewater management to chemical processing. Their ability to handle fluctuations in flow is commendable.

Durability is another significant advantage of rubber pump impellers. They can withstand abrasive and corrosive environments, extending their lifespan. However, it's crucial to note that regular maintenance is still necessary. Without proper care, even the best materials can degrade over time. Additionally, while rubber impellers are generally resilient, certain extreme conditions may expose vulnerabilities that need attention.

Another key feature is the noise reduction capability. Rubber impellers operate more quietly than metal ones. This can greatly enhance working conditions, especially in residential areas or sensitive environments. However, some users might find that noise levels can still vary based on design and installation. Choosing the right model is essential for achieving optimal performance.

Rubber pump impellers offer unique advantages in various applications. Their flexibility allows them to withstand high pressures and temperature fluctuations. According to a recent industry report, rubber impellers reduce the risk of wear and tear, leading to longer service life. Such durability means fewer replacements, which can save considerable costs over time.

In terms of performance, rubber impellers excel in handling corrosive fluids. This makes them ideal for industries like chemicals and wastewater management. A study noted that pumps with rubber components showed a 30% improvement in efficiency. However, they can perform less effectively in extreme temperature conditions. It's crucial to consider the specific environment before making a choice.

The installation of rubber pump impellers is often simpler than metal alternatives. This ease can shorten downtime during maintenance. Yet, one must be cautious; improper installation can lead to leaks and failures. A careful approach to fitting and alignment is necessary to ensure reliability.

Rubber impellers have gained attention for their durability. They resist wear and tear better than many other materials. This makes them ideal for challenging environments. Whether in water systems or industrial pumps, they hold their own against corrosion and abrasions. Rubber can endure tough conditions without losing performance.

The performance aspect is equally impressive. Rubber impellers provide a reliable flow rate. They can adapt well to various viscosities. However, not all rubber impellers are created equal. Some lack the strength needed for heavy-duty applications. Users must choose carefully based on specific requirements. Testing and feedback often reveal weaknesses in previous models. Such reflections lead to better designs over time.

Another notable feature is the quieter operation. Rubber dampens vibrations, contributing to a smoother experience. However, problems can arise if the design isn’t optimized. Improper fit can lead to inefficiencies. Regular maintenance is necessary to avoid performance drops. Overall, while rubber impellers excel in durability and performance, careful selection and maintenance remain crucial.

| Feature | Benefit |

|---|---|

| High Durability | Resists wear and tear in harsh environments, leading to longer service life. |

| Corrosion Resistance | Protects against chemical degradation, ensuring reliable operation with various fluids. |

| Flexible Design | Accommodates a range of flow rates and conditions, enhancing versatility. |

| Low Maintenance | Reduces operational costs with less frequent replacements and repairs. |

| Noise Reduction | Minimizes operational sound levels, promoting a quieter working environment. |

| Thermal Stability | Maintains performance under varying temperature conditions, ensuring reliability. |

Maintaining rubber pump impellers is essential for efficient operation. These components can wear down over time due to friction and corrosive environments. Research shows that regular maintenance can improve operational life by up to 40%. Proper care not only enhances performance but also saves costs in replacements.

One crucial tip is to inspect the impellers frequently. Look for signs of wear or deformity. Uneven surfaces can lead to inefficient pumping and increased energy use. Replace damaged impellers promptly to prevent additional system stress. Keeping the pump clean can also prevent debris build-up, which can compromise the impeller’s function.

Lubrication is another important factor. Ensure that the bearings are properly lubricated to minimize friction. This simple task can reduce wear and extend the life of your impellers. Data indicates that impellers with adequate lubrication have a 25% lower failure rate compared to those that aren't maintained. Regular performance checks and timely maintenance can lead to better reliability and operational efficiency. Remember, proactive care is key.

When comparing rubber pump impellers to those made from other materials, several factors come into play. Rubber impellers are known for their flexibility. This allows them to withstand vibrations and shocks better than hard materials. This adaptability is crucial in applications where the pump may face varying flow conditions. However, rubber impellers can wear down more quickly in abrasive environments.

On the other hand, metallic impellers offer superior durability. They can handle higher temperatures and pressures, making them suitable for industrial use. This strength comes at a cost, as they can be more expensive. Additionally, metallic materials may lead to cavitation issues, which can reduce efficiency. In contrast, rubber impellers are less prone to cavitation, but their lifespan may be shorter in certain conditions.

Buying choices depend on specific needs. Users must consider factors like the nature of the fluid, temperature range, and longevity of the impeller. Some users mistakenly assume that rubber is always the best option due to low initial costs. It’s important to evaluate trade-offs carefully. Often, a detailed analysis is required to find the best match for unique operational demands.

Content © 2025 Komatsu. All Rights Reserved